Penn State Intercom......November 15, 2001

Addition of clays make

better, cleaner plastics

By A'ndrea Messer

Public Information

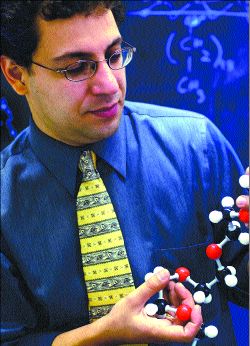

"Adding very small

amounts of natural clays to plastics changes some of their physical properties,"

said Evangelos Manias, assistant professor of materials science and engineering.

"While we can tune the chemical interactions between the clays and some

polymers, it is the general changes due to the nanometer fillers in all

plastics that may be the most interesting."

Addition of clay can

make plastics less permeable to liquids and gases, more flame retardant

and tougher. Lower permeability can make plastics like PET, the standard

plastic used in soft drink bottling, suitable for bottling beer or wine.

The clay-enhanced product would protect the beverages from the effects

of oxygen. At the same time, the addition of small amounts of clay does

not affect the transparency of plastics.

Adding clay to polymer

blends is not a simple process as polymers and clays mix about as well

as oil and water. However, if the clay is treated with an organic surfactant,

a compound that allows the inert clay to mix with the polymers, much as

soap allows oil and water to mix, the clays can be incorporated into the

final product.

An inexpensive, more

environmentally clean method of producing flame retardant plastics could

eventually save lives. Because the addition of clay into plastics reduces

flammability in a wide range of plastics, it may have universal application

as a general flame retardant additive.

"Currently, chemicals

used to make plastics flame retardant contain bromine, which produces poisonous

combustion gases when burned," Manias said. "Using clay is a green alternative

to current practices and reduces flammability in a wide range of plastics."

The polymer clay blends,

while containing only 1 percent to 5 percent clay, are

actually nanocomposites. The addition of clay into the polymer blend does

not alter the normal production and processing of the clayless polymer.

"The clay can be added

at the final stages of polymer processing without any change in the current

industrial practices," Manias said. "The thermodynamics drive the nanometer

dispersion of

the clay through the polymer and the small amounts of clay do not cause

any wear in the equipment. Manufacturers can use the same equipment, timing

and settings as in their normal process. Small

amounts of well-dispersed natural clay can lead to environmentally friendly

and inexpensive plastic composites with improved specialized properties,

according to a University researcher.

Small

amounts of well-dispersed natural clay can lead to environmentally friendly

and inexpensive plastic composites with improved specialized properties,

according to a University researcher.